PHONE: 416-298-9137

Capabilities

We have the latest technology in laser cutters, turret presses, robotic welders, and powder coating systems to deliver precision-built equipment.

Our team works with MIG, TIG, and spot-welding equipment to create our steel solutions, and we also handle the shearing, forming, punching, and finishing. In addition to our manufacturing facilities, we also have a dedicated facility for product assembly, product testing, storage, and distribution. When you’re ready to receive your equipment, we can ship it knocked down or deliver it to your business fully assembled. We pride ourselves on providing white glove service in an industrial sector.

The Calstone Benefits

-

Dedicated manufacturing facility

-

Product assembly

-

Product testing

-

Storage & distribution

Put our manufacturing capabilitiesto work for you

- Design-Assistance

- Laser Cutting

- Punching

- Forming

- Welding

- Painting

- Finishing & Assembly

- Logistics

Design Assistance

With a focus on optimizing effectiveness and efficiency, our design engineering team assists our customers to capture their design ideas and turn them into accurate drawings, proposals, and specialized plans for prototypes. Using a combination of design principles, the latest design software and engineering programs, our team can take a project from concept to a superior finished product according to custom specifications. Our design services include making recommendations on materials, design-assist, and installation techniques.

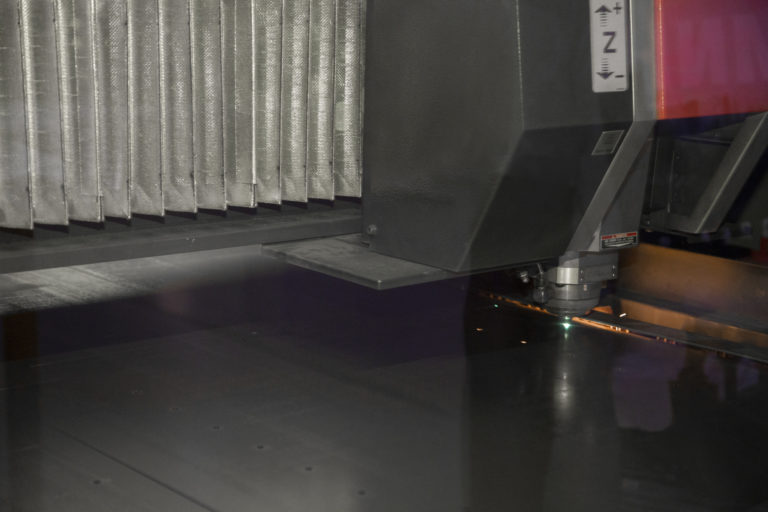

Laser Cutting

Equipped with multiple laser cutting machines that are fully automated with 24/7 lights out production capability, we are poised for greater efficiency and productivity. This automation technology eliminates the risk of operating errors, resulting in higher-quality products. Additionally, we can laser cut materials varying in size, shape, and thicknesses. The seamless laser cutting system effortlessly turns drawings into finished parts and reduces lead time by ensuring precise cutting, eliminating burrs, optimizing workflow and accelerate our production process while producing virtually no waste.

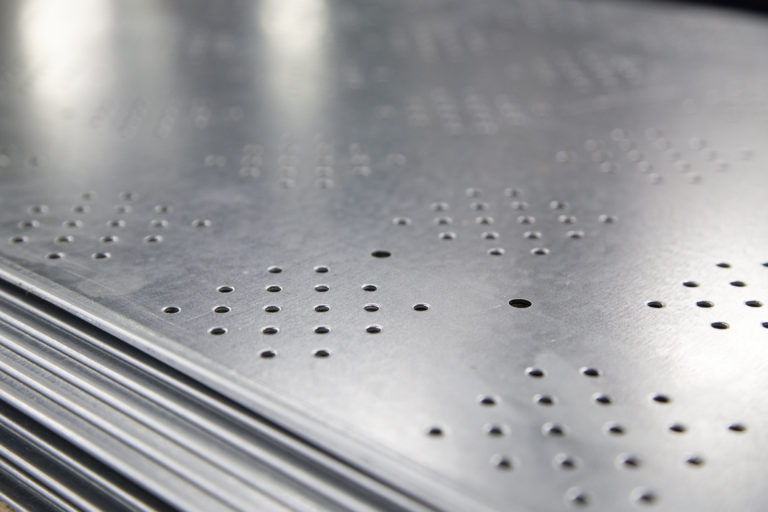

Punching

With the precision and speed of our Turret Punch Presses, we can offer optimum part quality. The AE NT Series was engineered as part of an ongoing commitment to provide manufacturers with the widest range of high-performance punching solutions. The AE NT Series is packed with a wide variety of standard features to ensure that parts are produced faster, easier, and more economically. The advantage of this punch technology results in high quality parts, excellent productivity, and tremendous flexibility. With efficient use of materials and high productivity, the cost-savings translate over to our customers.

Forming

Our automated press brake machines are ideal for series productions of both large and small projects. These Eco-friendly high-performance electric/hydraulic, down-acting systems deliver superior accuracy. This high-performance series features a Hybrid Drive system that is engineered for low energy consumption and requires less hydraulic fluid than conventional machines. The super-accurate ram is capable of repeatability to within tolerances of ± 0.030”.

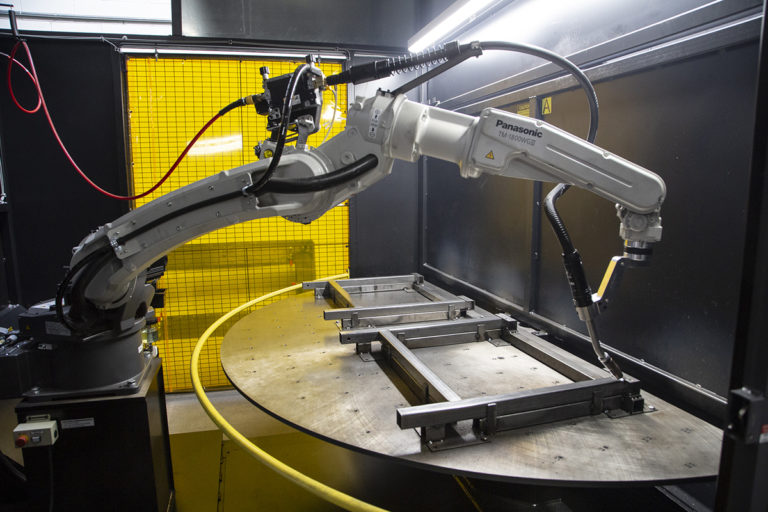

Welding

Our emphasis on quality is second to none with products made with structural integrity and of superior quality. Our full range service includes MIG, TIG and spot welding. We are an ISO 9001 registered company with certified welders and supervisor personnel. We ensure that our work is guided by the highest standards of quality and safety. We also have 2 robotic welding systems that are three times more productive than manual welding. This increases productivity and quality while minimizing downtime.

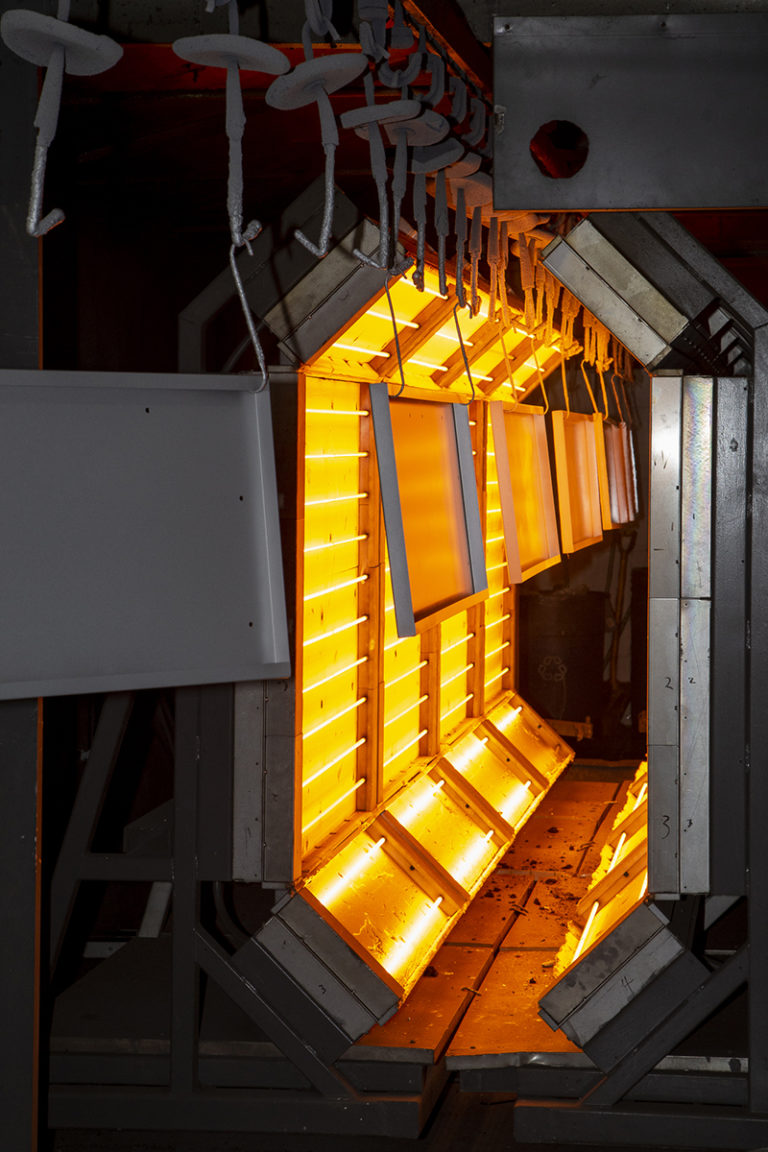

Painting

Calstone utilizes two in-house Automated Electrostatic Powder Coating paint lines. Our professional and highly skilled painters ensure a superior finish is applied to all parts. Powder coating is a multi-step surface finishing process that provides a high-quality, lasting finish on your metal products. Parts are inspected and approved before moving into the assembly stage of our process.

Finishing & Assembly

Our assembly team has extensive knowledge of how our products are manufactured and fasten together. The team has access to detailed engineering drawings and utilize environmentally friendly packaging materials. Our precision packaging allows for the protection of our products during transit and prevents damages so that our customers receive their products in “ready to use” condition. We provide our customers with either knocked down shipments which include assembly instructions and hardware, or fully assembled shipments if installation timeframes are tight. All shipments are shrink wrapped, well labelled and accompanied by a packing slip. Shipments can be colour coded if required. We provide tracking information and delivery confirmations.

Logistics

Our logistics team provide outstanding supply chain solutions to ensure smooth and seamless delivery of product shipments. After you place your order, we make it quick, easy, and convenient to receive your order. We will handle all shipment and export documentation required, ensure customs compliance, coordinate and schedule transportation, track, and promptly update shipment status. Our goal is to enhance our customers experience by providing exceptional service.

Solutions that work

We have end-to-end solutions for all your steel-based furniture needs.